Cleanroom build of spray dry plant for small scale production

n designing the specific spray dry plant for small scale production (≤ 1 MT/yr) for VitaSquare Wolvega Netherlands, Kropman Contamination Control looked at many design considerations

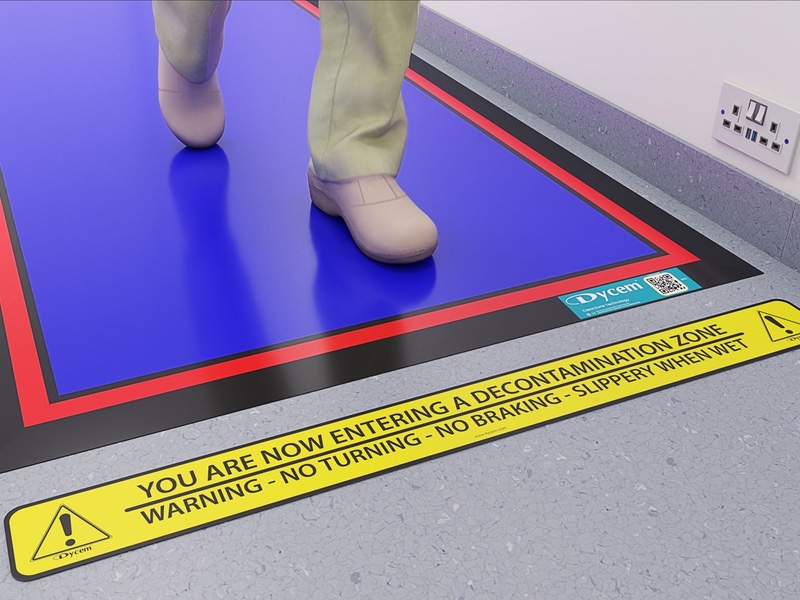

Image 2

Image 2

VitaSquare Wolvega produces nutritional premixes. In the Netherlands, the company enriches dry or ‘instant’ food with vitamins, amino acids, minerals, trace elements, and many more components.

For this to work, the nutrients need to be added in powdered form.

For the design of the specific spray dry plant for small scale production (≤ 1 MT/yr), many design considerations are implemented.

First of all process steps are identified and assessed for: product susceptibility, the risk of spilling, the method to clean in place as well as the exterior, including the room. Logistics of materials, product, staff and waste are also planned for.

Dosing and fine ingredients mixing

Logistics are set up to handle most raw material in bulk containers, positioned outside the process rooms, are hooked up to the process lines (Image 1). This all is done in a non-classified but controlled area of basic hygiene level.

Image 1

Image 1

Spilling is not expected as all raw materials here are in containers or per piping such as feed water. Also, the CIP and waste flows are run as fixed piping. Specific additives are added in the processing room via a tank lid. (Image 2)

The tank itself is at the other side of the wall, with all its pumps, valves, sensors, actuators, wiring and supports. This leaves the processing room quite easy to clean. The various connections for the process and transfer steps can be made by transfer panels. The fine ingredients come to this processing room by an elevator from the ground floor. The elevator acts as an airlock as it is interlocked and flushed by overflow air maintaining the pressure flow cascade.

As shown in images on p55, the logistics are well separated as well as the majority of the process equipment is located in a non-classified hygienic zone. The area of exposure is very limited and in a controlled; ISO Class 9 environment.

Image credit: Dycem

Image credit: Dycem